Describe the Process of Printing Using Lithography

Printed using the lithographic process there are ways of reducing the size of the halftone or screen tint dot on the printing plate that will print the magenta ink. Because mistakes at this point can easily destroy the drawing on the stone great care must be taken to proceed correctly and to understand fully each step involved.

Roller or cylinder printing Sometimes called machine printing this is a gravure printing process used for printing on textiles.

. Stereolithography is an imaging progression which is used to create unique 3D-printed objects. This plate prints an area half the size of the sheet. The printing plate is kept dampened.

In modern lithography aluminium sheets are usually etched through CAD-enabled machinery either using an electromechanical stenciler or an etching laser. A sheet of paper is then placed on the plate and pressed so the design is transferred onto it producing the first lithographic print with very clear and precise lines. Pad printing is limited to small surfaces and used to print watch dials gadgets toys car parts etc.

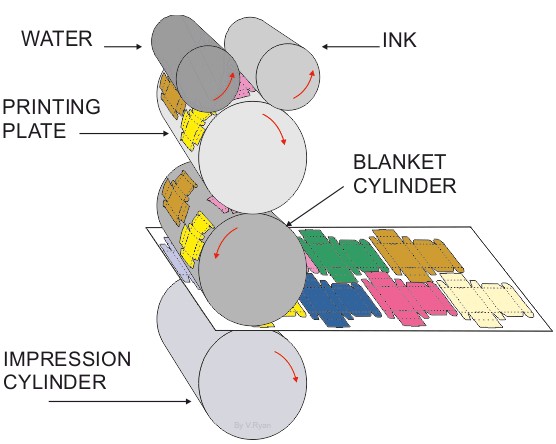

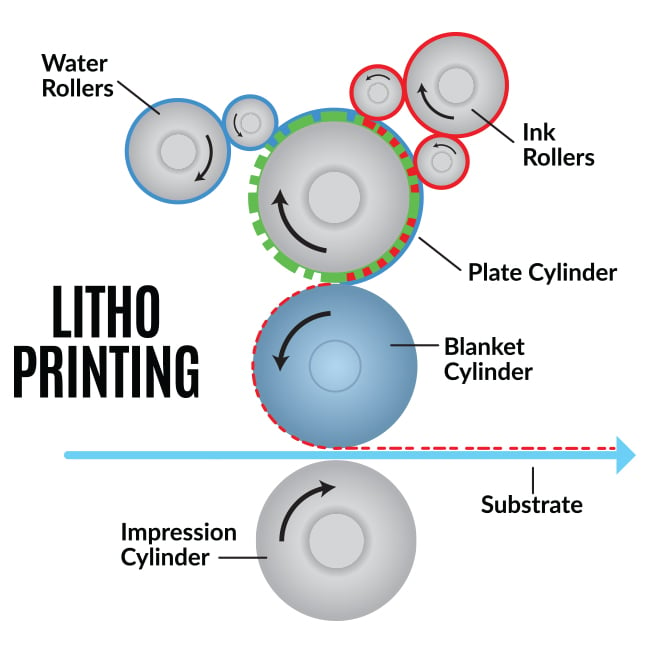

The offset image is then run quickly onto a print spool transferred via a conveyer belt underneath the rollers. These plates can be made out of stone metal aluminum etc. In the first stage the plate is passed through dampening rollers which provide a mixture of water and chemicals.

Lithography is the process of printing that uses the immiscibility of grease and water to create a high-quality print and can be used to print text or artwork onto paper or various other materials. Remember lithography is the art of printing from a flat stone limestone or metal plate by a method based on the simple fact that grease attracts grease as it repels water. Offset refers to the fact that the image is not transferred from a lithographic printing plate to a sheet of paper.

Basic lithographic process Processing the drawing to prepare it for printing is one of the critical phases of lithography. Density is the intensity or visual strength of the ink that influences the color quality of the final printed image. The word lithography is derived from the Greek word lithos meaning stone and graphein meaning to write.

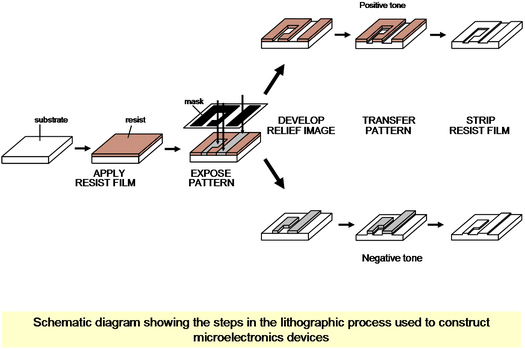

Optical lithography is basically a photographic process by which a light sensitive polymer called a photoresist is exposed and developed to form three-dimensional relief images on the substrate. This process can be repeated again and again even hundreds of times by inking and dampening the same plate. The 220 lb Crane Lettra paper double than the standard 110 lb weight and more than twice the cost allows for a.

The unique 3D printing machine also referred to as stereolithography apparatus converts liquid plastic into solid objects. Ink is applied to the plate but it is repelled from the dampened surfaces which. In general the ideal photoresist image has the exact shape of the designed or intended pattern in the plane of the substrate with vertical walls through the thickness of the resist.

Images words and art are put on plates see the next section for more on this which are dampened first by water then ink. Lithography currently the dominant printing technology is an indirect offset process. The sheet of paper is hand-fed through the press twice once from each end of the paper.

Image carriers In relief printing the image or. Nonimage blank areas which hold moisture repel the lithographic ink. Overall it can be seen that the process by which newspapers are printed from lithography is a multistep linear process which consists of 5 stages.

Lithography printing right off the stone surface could lay down a beautiful solid layer of ink. After the image is applied to the printing plate through a photochemical mechanical or laser-engraving process the. Then the image is transferred to a rubber blanket and from.

As soon as light-sensitive metal plates replaced the stones the halftone fully refined in letterpress printing could move into lithographythe old laborious translation of pictures by hand could be mechanized through the halftone screen. This produces 8 cards per sheet in a process called a work-and-turn. The printing plate has the image to be printed in relief on its surface the image stands out slightly from the.

The figure depicts the process of generation of lithography. This is the offset part of the printing process. Offset printing or offset lithography is a printing press technique that transfers the ink from a plate to a rubber roller or blanket and then to various substrates to produce high quality images and designs.

You can see the result here. The root words photo litho and graphy all have Greek origins with the meanings light stone and writing respectively. Ink and water dont mix.

An image is transferred from an engraved printing plate onto a three-dimensional surface using a silicone pad. Lithographic printing is a style of printing in which an image is transferred to a printing plate which is then covered with both water and oil-based ink. Lithography is a printing process in which the image area and the non-image area co-exist on the same plane.

In full-color printing standards have been estab-. The ink adheres to the image area the water to the non-image area. Both terms each describe part of the process.

Offset lithography works on a very simple principle. In the lithographic process ink is applied to a grease-treated image on the flat printing surface. As suggested by the name compounded from them photolithography is a printing method originally based on the use of limestone printing plates in which light plays an essential role.

This inked surface is then printedeither directly on paper by means of a special press as in most fine-art printmaking or onto a rubber cylinder as in commercial printing. In the 1820s Nicephore Niepce invented a photographic. A design or image is drawn on the surface in this case a piece of limestone with a greasy material grease crayon pencil or ink and then water and printing ink are applied.

The process of lithography is a printing process where the image to be printed is transferred to a flat smooth surface called a printing plate through a chemical process. As the printing cylinder rotates the ink is. Lithography utilizes the natural resistance of oil and water to mix.

The Process of Stereolithography.

Litho Lam Printing Vs Digital Printing For Retail Packaging

What Is Litho Lithographic Printing Blog Kms Litho Ltd Oxfordshire

Photos Of The Creation Of A Lithography Print Printmaking Lessons For Kids

Lithography Hisour Hi So You Are

How To Make A Lithographic Print Youtube

Lithography Process Video Printmaking Khan Academy

What Is Litho Printing Is Lithography Still Relevant

Offset Lithography Offset Printing Technology Offset Lithography

Schematic Illustration Of The Lithography Offset Printing Process Download Scientific Diagram

Polymetaal Lithography Definition And Historical Outline Beguin

Photos Of The Creation Of A Lithography Print Printmaking Lessons For Kids

Offset Lithography What Is Design Printing Labels Lithography

To Know More About Plastic Card Company Plastic Card Offset Printing Lithography Prints

The Best Printing For Packaging Pros And Cons Of 5 Printing Methods

Offset Printing The Printer Quality Offset Digital Printing 530 753 2519 Davis Ca

Lithography An Overview Sciencedirect Topics

Offset Lithography Printing Process Rosa Et Al 2015 Download Scientific Diagram

Printing Methods Lithography Flexography Printing Printing Methods Prints

Comments

Post a Comment